WELCOME TO CASTECH 3D - YOUR FIRST CHOICE FOR 3D PRINTING

FAST COMPLETION

LATEST TECHNOLOGY

LATEST TECHNOLOGY FOR SPEED, PERFORMANCE, AND ACCURACY IN 3D PRINTING

Castech, 3D Printing Australia, has embraced cutting-edge technology, now utilising 3D printing to provide you modern solutions for speed, performance, and accuracy. Call us today!

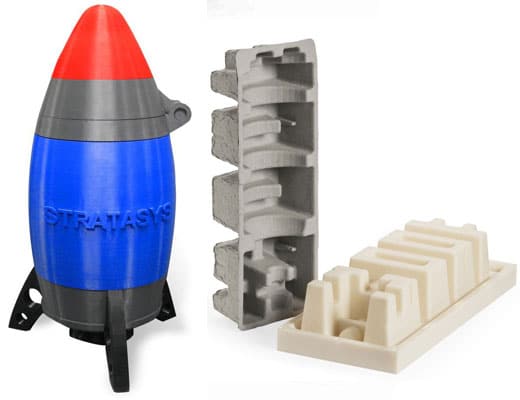

The Fortus 450MC printer is capable of printing patterns, coreboxes and prototypes for easy product visualisation and creation. Products are printed from 3D CAD models, resulting in quality and detail suitable for a range of industries. The Stratasys Fortus 450MC – the first and only of its kind in South Australia – can print as large as 406mm x 300mm x 406mm or split parts into joint sections. Read More

MADE FOR PRODUCTION

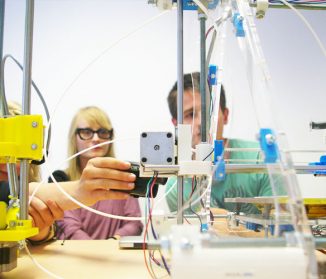

Castech 3D is an industry expert, providing quality 3D printing made to last. With a team of 3D printers, suitable for a range of applications, Castech 3D has the capacity to rapidly print one offs or large volume prints in the thousands.

Our knowledgeable technicians can walk you through the best settings for your desired print, helping you decide on print quality, density, durability and design.

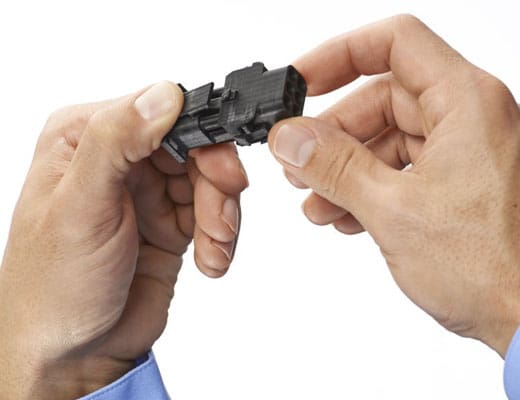

We can offer prints for a variety of solutions – UV resistant, water-tight or even movable parts printed without assembly

SUPERIOR PRINT QUALITY

At-home, desktop 3D printers often provide less than desirable prints – cheap and roughly made DIY jobs not suitable for production parts or even small scale parts.

print is optimised for speed, performance, accuracy and, of course, quality.

With an impressive workforce of 3D printers to bring your ideas to life, whether it is 3D model printing, rapid prototyping, or something of your own creation.

quality 3D printing in Australia. Tough enough for use in the real world.

BRING YOUR IDEAS TO LIFE

PHONE: +61 8 8349 7299

OUR CUSTOMERS – LOCAL AND GLOBAL

Castech is not new to business of customer satisfaction, we have an experienced team working to optimise your customer experience.

3D printing can provide innovative and dynamic solutions to anyone – be it an individual or a large organisation.

With many suitable 3D printing applications, our team has provided 3D printing solutions for defence, IT electronics, automotive, medical, foundry, entertainment, education and even your neighbour with the broken roller door.

We are not limited in our capacity to 3D print, nor our capacity to deliver these 3D printing services Australia wide and global. Waiting times are a thing of the past, 3D printing provides some of the quickest manufacturing turnarounds – get your parts swiftly, wherever you are located.

OUR PROCESS

01 CONTACT

02 SEND CAD DATA

03 GET QUOTE

04 ORDER

05 DELIVERED

SUSTAINABILITY

There are two key elements that give additive manufacturing the quality of being sustainable, green technology.

1 – REDUCED WASTE

Unlike traditional subtractive manufacturing, our 3D printers only use materials as required when building each layer.

2 – GREATER ACCESSIBILITY

Our team of in-house 3D printers means no additional tooling or third-party materials are required, thereby reducing logistics and travel issues often seen with conventional manufacturing methods.

NEW PARTS - WE CAN PRINT IT AND PAINT IT

PRODUCT DEVELOPMENT |

ARCHITECTURE |

ENGINEERING |

CALL US TODAY TO RECEIVE A QUOTE

PHONE: +61 8 8349 7299

RAPID PROTOTYPING

TOOLING

MANUFACTURING

WHAT IS 3D PRINTING?

CASE STUDIES

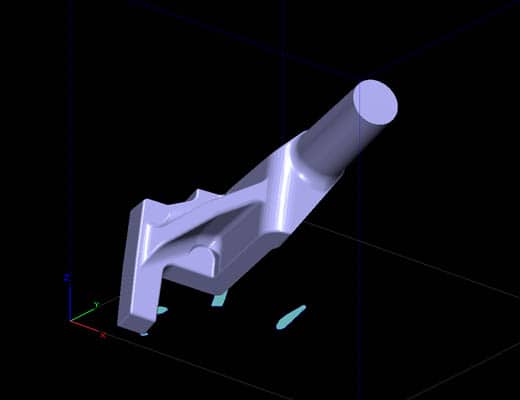

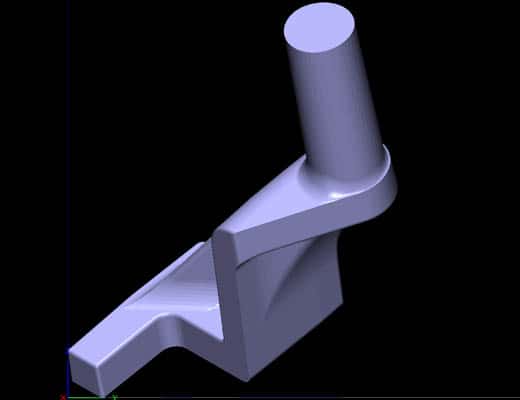

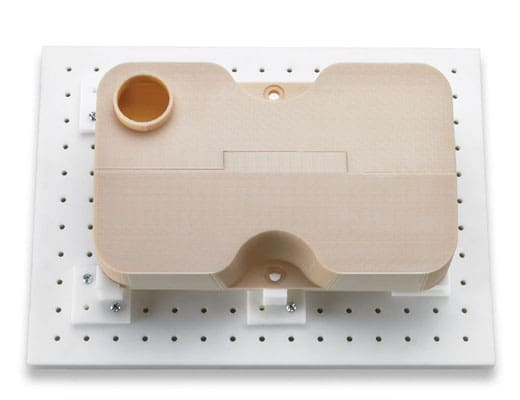

Client requires a 3D printed model to use as a pattern for the manufacture of a cast journal bracket and provided Casted 3D with a 3D CAD model of the journal bracket. Our technician liaises with the client in order to determine the product’s strength requirements and desired finish then imports the 3D model into our ‘Insight’ programme and manipulates the model in order to decide which printing technique to utilise. Ensuring to take into consideration several factors including: slice height (resolution), support material, fill density and product orientation. We send the file to the Fortus 450 MC for printing. This product was then printed over 19 hours- however, the printing time required can take as little as 2 hours depending on a product’s resolution and total material.

Printed model incorporating the support material is removed from the printer. Support material is removed from the printed part. Final finishes are made to the client’s request. The technician can smooth part surfaces and apply a protective, finishing coat. The part is then delivered to the satisfied client within 48 hours of their purchase order.